Laser Transmission Welding/Laser Plastic Welding

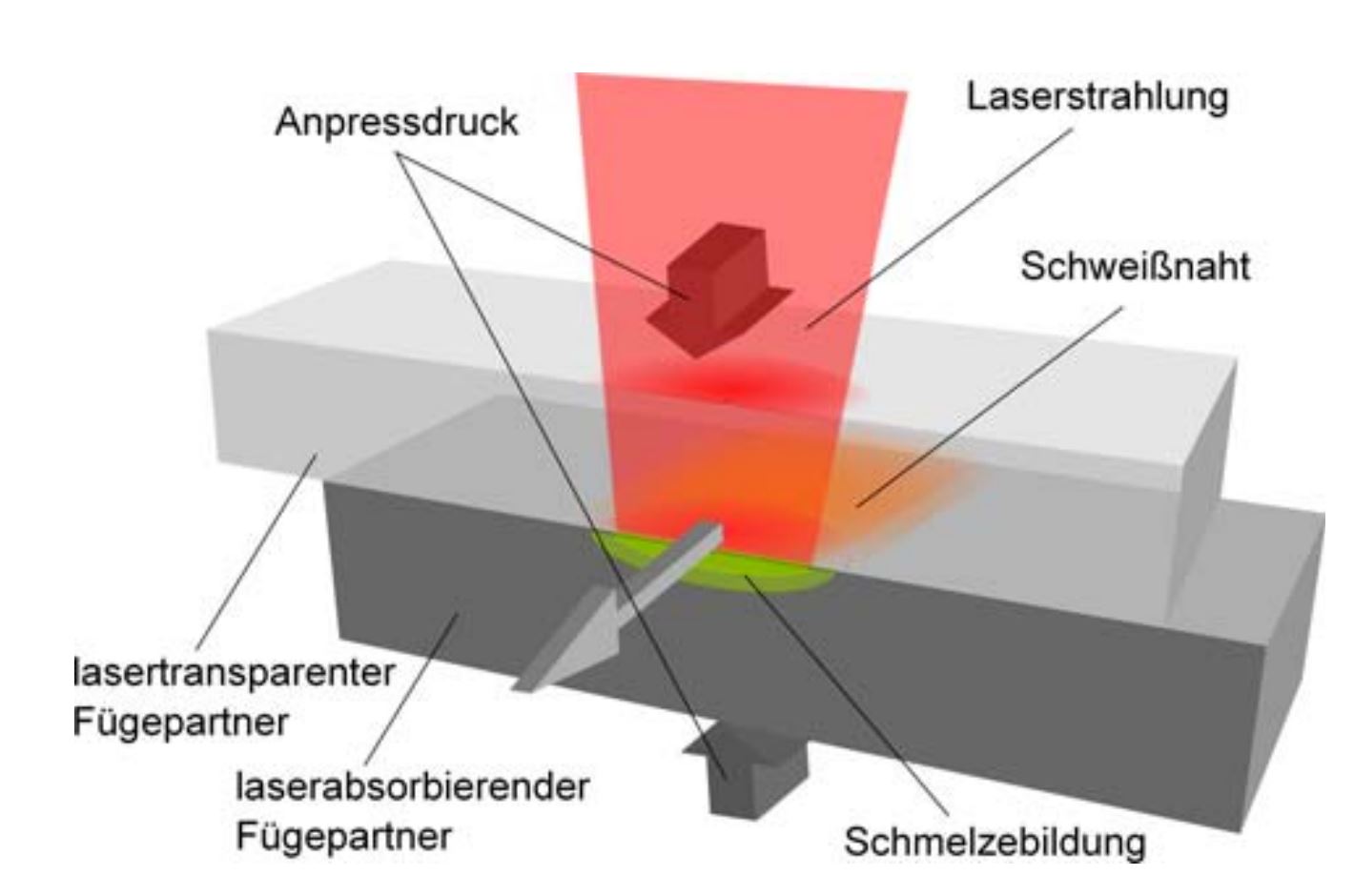

Plastic laser welding is a process that uses a laser to melt and fuse plastic parts. The basic principles of plastic laser welding are to heat the intermediate layer of plastic parts with a laser beam until they melt, and during this process to press them together to form a permanent bond.

Some of the main elements of plastic laser welding are explained below:

Laser source: A laser beam is generated by a laser source, which is usually a fibre or diode laser.

Optics: The laser beam is passed through a series of mirrors and lenses to focus it on the area where the plastic parts are to be welded.

Materials for welding: The plastic to be welded must be suitable for laser welding. Common plastics used in laser welding include PA, PC, acrylic, ABS and PMMA.

Design of the joint: The design of the joint to be welded is critical to the success of the process. The joint must be designed so that the laser beam can reach the welding area.

Process control: Laser welding requires precise control of the laser beam and the welding process. Factors such as power, speed and focus of the laser beam must be carefully controlled to achieve a successful weld.

Laser welding of plastics has many advantages over conventional welding methods, including faster welding speeds, greater precision and less deformation of the welded plastic. It is used in a wide range of industries, including automotive, medical and electronics.

Laser welding of plastics has many advantages over conventional welding processes, including faster welding speeds, greater precision and less deformation of the welded plastic. It is used in a variety of industries, including automotive, medical and electronics.

Here, pressure/laser power/scanning speed can also be used to weld different thermoplastics together.

We support with:

- Material selection

- Component design

- Injection molding

- Laser welding as a service

- Laser marking

- Service & Commissioning

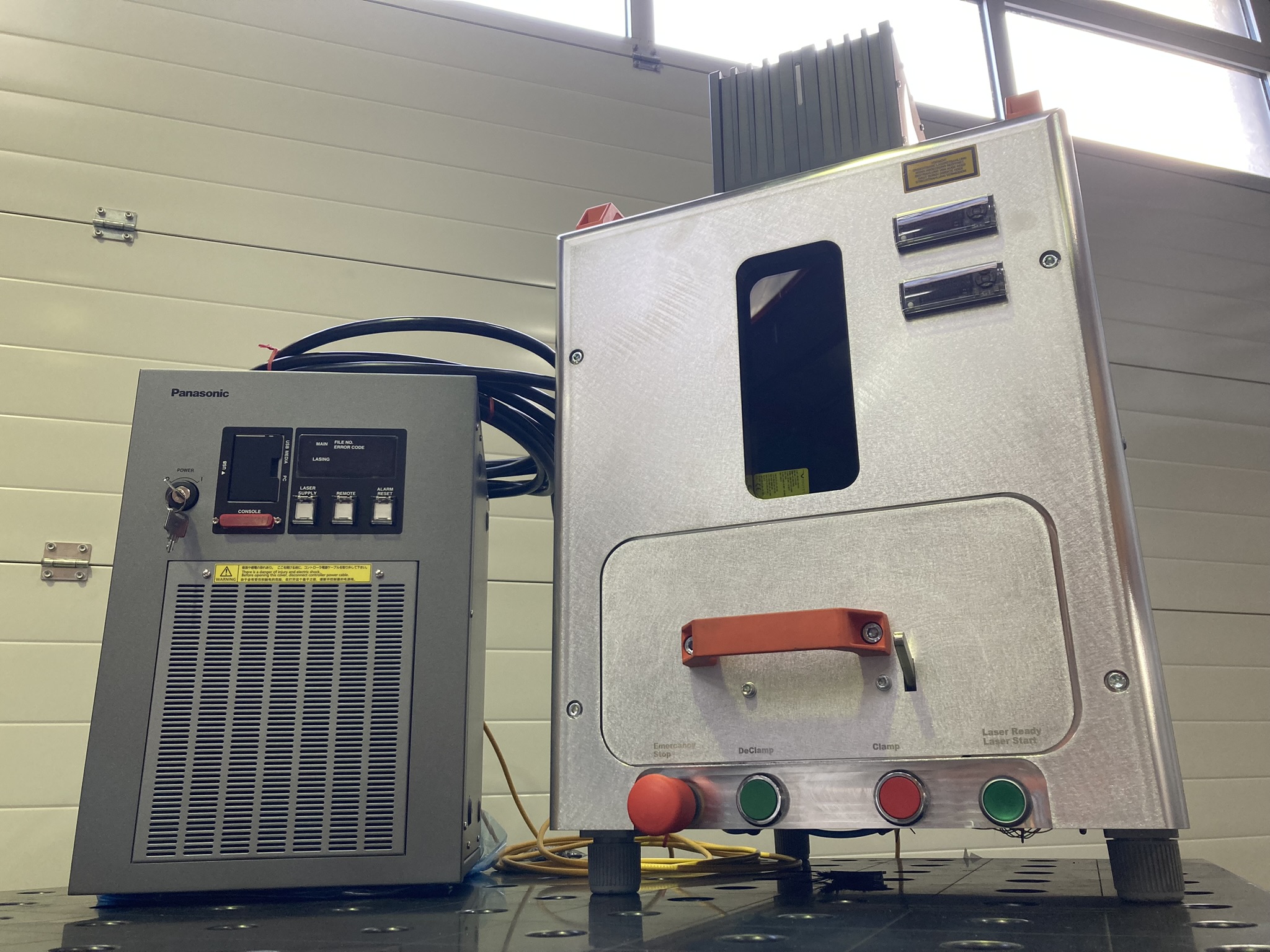

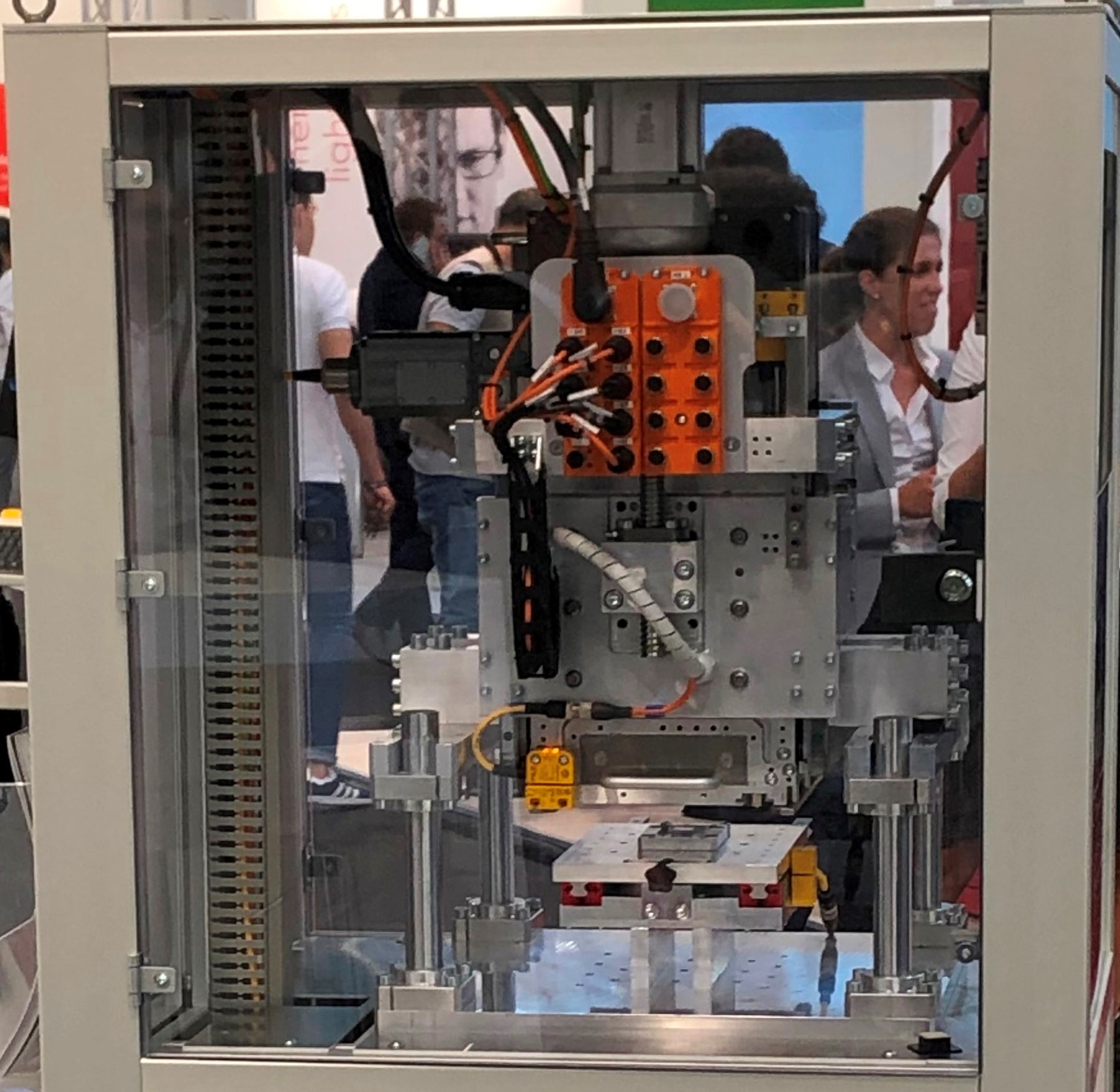

machine concepts:

| MK-LW mini | MK-LW light | MK-LW inline | MK-LW robust |

|

200x200mm workfield pneumatic driven loading via drawer |

200x150mm workfield pneumatic/Servo/springloaded driven loading via turntable |

200x150mm workfield pneumatic/Servo/springloaded driven loading via turntable/conveyor |

400x400mm workfield pneumatic/Servo/springloaded driven double clamping loading via turntable/conveyor |

|

cycle time>20sec |

cycle time<10sec |

cycle time<10sec |

cycle time<15sec |

|

|

|

|